Highlights of CAT Caterpillar ET diagnostic adapter iii:

1.It is the latest generation of the CAT Communication Adapter group, and replaces the CAT Comm Adapter II.

2.This is the only recommended communication device for CAT, and the only datalink device that will allow you to properly communicate with a

CAT engine on dual datalinks.

3.This function is needed for some CAT ET (Electronic Technician) functions.

Communication:

Allows communication between service tools and engine controls using various data links such as J1939/11, DeviceNet (future release), CAT DataLink, and J1708 (ATA) vehicle networks;

Flash program allows adapter firmware upgrades as additional features become available;

Uses J1939/11, high-speed data link (part of ADEM III controls), substantially reducing flash times;

Automatically selects J1939/11 when flashing the engine (reduces the flash time approximately 80%, from 14 minutes to 3 minutes).

Whats Includes:

1.Used Dell D630 laptop

2.Real CAT et3 Comm Adapter III(it’s best quality cat et 3,not adapter 2,please check Communication port)

3.USB Cable (From device to your computer)

4.J1939/J1708 9PIN Cable (from device to your truck)

5.6PIN Cable (for old truck)

6.14PIN Cable(for new truck)

7.Plastic box

Software:

Designed to run with Microsoft Windows 95, 98, 2000, NT and XP

Ready to use, just install software program onto PC using provided CD

Brand: Caterpillar

Region: WorldWide

Support Multi-language:English, Chinese, Danish, French, German, Italian, Japanese, Portuguese, Russian, Spanish

Support All cars of CAT

The PC-based service tools from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool. The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more.

The service tool works with a communication adapter to allow connection to an ECM. A graphical interface makes this software quick to learn and easy to use. A separate pull-down menu for each function enhances the a ease of use.a? The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started.

Diagnostic tests and calibrations can also be performed.

Caterpillar PC-based tools enable service technicians to reprogram ECMs, reconfigure control system parameters, fine tune performance or diagnose the root cause of a failure the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately. The service tool communicates with any system using ATA (J1708), J1939 or the Caterpillar proprietary data link networks. The service tools provide information and features needed to help a technician diagnose problems and perform repairs and to customize and personalize the operation of a product. By allowing customers to design flexibility and configurability into a product, Caterpillar service tools stretch beyond the capabilities of preprogrammed ECMs or onboard display systems.

Features:

Display graph and log status parameters.

Retrieve prognostic data including histograms, engine totals for fuel used and miles traveled.

View active diagnostics and clear logged diagnostics. View events where irregularities have occurred and have been logged by the ECM.

Perform calibrations to enhance performance of the ECM.

Customize the ECM with application-specific settings.

Over 100 custom Diagnostic, Information and Service features including:

2D and 3D Histogram plotting capability (engine software support required).

Custom Status screen groups

Snapshots (Download and display snapshot data recorded by the ECM)

Configuration Aid that allows upload/download of same configuration to multiple control modules

Customised Service Tool Options

Customized service tool name

Customized graphics for the splash screen and icons

Customized installation

Aftermarket differentiation, the tool for one customer does not work on the product of another customer.

Licensing options for customer management

Flash programming of the ECM(s)

Training demonstration allows familiarity with the toola s primary functions without connecting to ECM(s)

Major operating systems support (Microsoft Windows 95, 98, NT 4.0, 2000, ME, & XP)

Perform customized diagnostic tests to identify harness problems, cylinder or component failures (Automatic Cylinder Cutout with cylinder to cylinder fueling comparison)

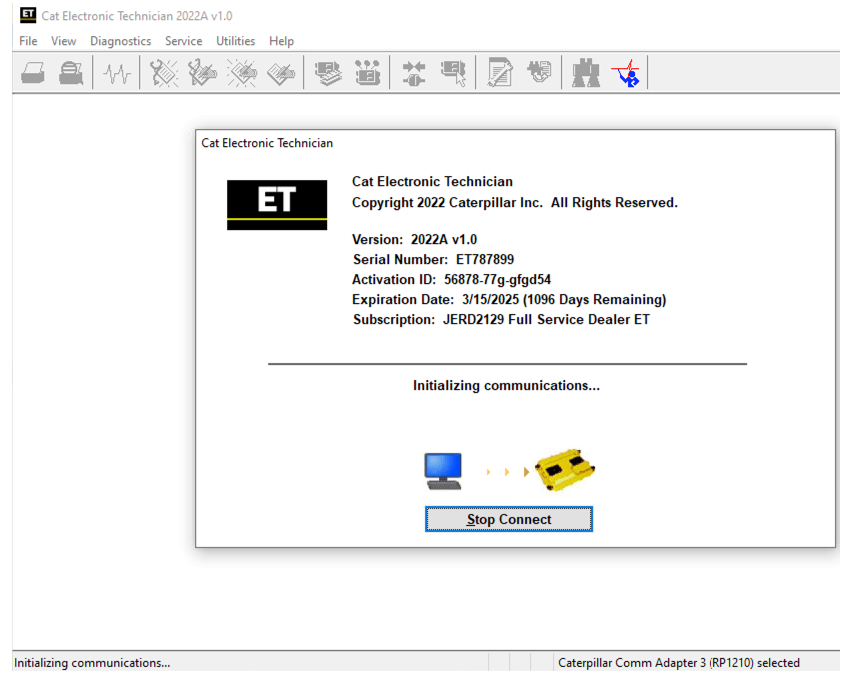

What’s New – 2022A

Microsoft® Windows™ 11 Compatibility

Service tool testing has been performed and the service tool is compatible with Windows 11.

ECM File Replacement Compare Feature

The service tool now has an ECM Replacement File Compare feature for troubleshooting purposes. This feature allows the user to compare one ECM replacement file with another from within the ECM Replacement feature screen. The feature will highlight the differences between the selected files as a whole or the user may select the “only show differences” checkbox.

Configuration Group Headings on ECM Replacement Feature

In order to help the user find ECM replacement configuration items easier, configuration items in the ECM Replacement, Fleet Configuration, and Product ECM features are now grouped under their group sub-headings, as is done in the main configuration feature.

What’s New – 2021B

Product Status Report Updates

The Product Status Report has been updated to include throttle configuration information.

Please feel free to contact us ,If you have any question:

Live Support: Chat with us online

Whatsapp: +8618437976115

Email: sale@cnautotool.com

Skype:cnautotoolcom

Please bookmark our website so that you can check the order information and contact us.

Leave a Reply